What Is Roof Flashing? The Ultimate Guide 2023

1 February 2023

A home's roof is essential to protect us from the elements, including keeping water out. Yet, many of us don't give much consideration to our roofs, including the terminology used in roofing.

One crucial element of roofing is roof flashing, which is vital in ensuring a home's waterproofing and preventing costly damage from water intrusion. Roof flashing is designed into a roof's structure to stop moisture from causing issues like rot, mould, and structural damage.

This article will explore the significance of roof flashing, its materials, and the future of roof flashing in Australia.

What Is Roof Flashing?

Roof flashing is a thin material that professional roofers use to direct water away from the critical areas of the roof. It's a crucial roofing feature that every roof needs to have.

Where a roof meets a vertical structure, there are natural weaknesses, including areas of discontinuity like joins and penetrable sections.

Penetrable sections include holes or openings in a roof's surface that allow for structural elements like flues, skylights, vents, and chimneys. Areas where joins occur, include gutters, walls adjoining roofs, and door and window frames.

If not properly sealed, these all become entry points for moisture. However, creating an entirely waterproof joint between two surfaces can be challenging. Sealing penetration areas can also be difficult as the intersections contract and expand when humidity and temperature change.

So rather than relying on sealants alone, roof flashing is used as part of a home's overall weather-resistant barrier system. Flashing is a method for keeping water from entering a structure and keeping everything sealed while allowing for movement. It is installed strategically on a roof to create a more weather-resistant system.

Why Is Roof Flashing Important?

Ultimately, the purpose of roof flashing is to protect your roof and its troubled areas from water and other damaging elements. Those hard-to-reach areas can be the first to go without proper flashing, so it is imperative for the life of your roof to have roof flashing installed correctly to divert water off your roof.

If not installed properly, areas around vents or the chimney could pool water. This water can damage roof areas, creating discolouration and even leaks. Those leaks can be a real trouble area if left unchecked, potentially causing structural damage if left unchecked.

Australia is a country that experiences a range of weather conditions, from hot and dry to rainy and windy. This means that it is essential for buildings in Australia to have a solid and durable roof that can withstand the elements.

What Are The Benefits Of Installing Roof Flashing?

There are several benefits to installing roof flashing in Australia, including the following:

Protection from water damage:

The most obvious benefit of roof flashing is that it helps to protect the building from water damage. By preventing water from seeping into the building, roof flashing helps to keep the roof, the walls, and the interior of the building dry and free from damage.

Increased longevity of the roofing system:

By protecting the building from water damage, roof flashing also helps to increase the roofing system's longevity. A well-maintained roofing system protected from water damage will likely last longer and require fewer repairs, saving homeowners money in the long run.

Improved energy efficiency:

Roof flashing can also help to improve the energy efficiency of the building by preventing air leaks. When air leaks are controlled, the building is better able to retain heat in the winter and stay cool in the summer, which can lead to lower energy bills.

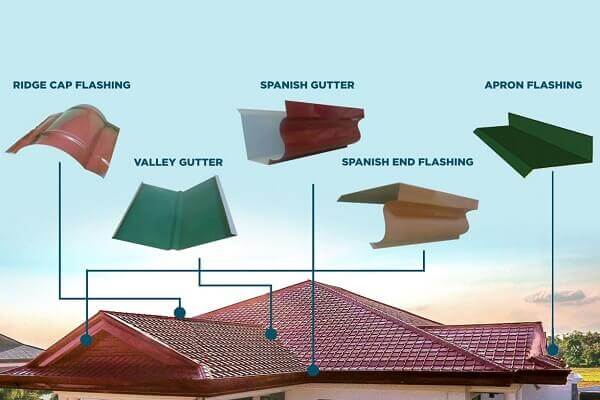

What Are The Different Types Of Roof Flashing?

There are almost as many roof flashing types as parts of the roof! After all, each roof feature needs protection. The different types of roof flashing include:

Continuous flashing:

Also called "apron flashing" because it acts a lot like an apron. Continuous flashing protects the joint between a vertical wall and a sloped roof.

Base flashing:

Some roof features, such as chimneys, require two pieces of flashing. Base flashing ensures that water always encounters a flashing surface that guides it away from the roof.

Counter flashing:

Counter flashing either goes on top of base flashing or opposite it. It is the second piece required to complete the base flashing. Counter flashing is used on walls and chimneys like step flashing.

Step flashing:

Step flashing protects where the roof meets the side walls, chimneys, and some skylights. It consists of a series of right-angled metal pieces; each section is worked into a course of shingles to overlap the area beneath it.

Drip edges:

Drip edges are a piece of angled flashing installed on the roof's edge. It contains a small metal flange that directs water away from the fascia.

Kickout flashing:

Kickout flashing bridges the gap between where step flashing ends and the gutter begins. Kickout flashing closes the space and keeps water away from the wall by redirecting it into the gutter.

What Areas Of Your Roof Require Roof Flashing?

Roof flashing is placed around objects or discontinuities which protrude from the roof of a building to deflect water away from joints or seams in valleys where water run-off is concentrated.

These parts of roofs and exterior walls are particularly prone to leaks and water damage. The areas that require the extra protection that flashing provides include:

Wall flashing:

Wall flashings are required at openings, corners, intersections, and wherever a roof terminates into a wall. Step and kick-out flashing where an existing roof meets an existing wall as part of a roof wall flashing are used to divert moisture, which has entered the wall, to the outside before it can cause damage.

Chimney flashing:

Chimney flashing is mainly comprised of counter flashing. Without chimney flashing, rainwater would easily leak into the house along the base of the chimney. Flashing is applied around the base of a chimney in several parts—continuous flashing along the bottom, step flashing up the sides, and saddle flashing at the top.

Skylight flashing:

A crucial part of any skylight installation is the flashing system surrounding the roof skylight. The skylight curbs are flashed with continuous flashing along the base, step flashing up the sides, and saddle flashing across the top.

Valley flashing:

Valley flashing is an essential component of your roof's flashing system. It protects the critical area of the roof where two slopes come together to form a valley. This flashing will effectively direct the water run-off down the roof and into the gutters when properly installed.

Vent pipe flashing:

Vent pipe flashing fits over flues and pipes. It is cone-shaped with a flange at the base, which is worked into the shingles as the roofing is applied. Vent pipe flashing is for waterproofing pipe penetrations of a roof.

What Is Roof Flashing Made Of?

There are a few different options to choose from for your roof flashing. Flashing can be composed of many different materials, but traditionally is made from a metal like aluminium, copper, painted galvanised steel, stainless steel, zinc alloy, terne metal, lead or lead-coated copper.

However, with the advent of new technology and manufacturing techniques, plenty of lead flashing alternatives are now readily available.

Lead roof flashing:

Lead is very malleable, making it easy to bend into intricate shapes and sizes to suit every application, unlike hard metals, which require special machinery to fold. As lead can be bossed or cut and welded, it can overcome any detail whilst not compromising the waterproofing and effectiveness of the lead.

Non-lead roof flashing:

There has been a growing trend toward using lead-free roof flashing products in recent years. Used anywhere traditional lead is used, the liquid polymer lead-free roof flashing alternative is lightweight, quick to install, BBA Certified, lead-free & PVC free, affordable, versatile and malleable, waterproof and long-lasting.

Aluminium roof flashing:

Aluminium is lightweight and easy to install. Before roofing contractors can install aluminium, they coat it with masonry and concrete to prevent corrosion. Aluminium flashing is very popular for do-it-yourself installation because it's easy to bend.

Copper roof flashing:

Copper is malleable, easy to solder, and a highly durable material with a long lifespan, but as copper ages, it fades into a patina. Copper flashing is usually custom fabricated for use with copper roofs.

Steel roof flashing:

Steel flashing is malleable and aesthetically appealing. To prevent corrosion, steel flashing is galvanised. The most common type of metal used for roof flashing today is steel. It gives you a clean look that fits most budgets.

Lead vs Lead-Free Roof Flashing

Lead has been the material of choice for roof flashing for centuries due to its durability and long life span. However, an increase in worldwide lead prices has resulted in several alternatives gaining popularity. For generations, lead flashing has been used simply because no materials or technology were available to create anything better.

Lead flashing was used to seal roof penetrations and prevent rainwater from leaking into homes. While practical and versatile, lead flashing comes with some disadvantages; lead mining can be an extremely destructive practice, and there's a high risk of poisoning when working with lead flashings.

These drawbacks have been enough for some to want to look elsewhere. Fortunately, with the advent of new technology and manufacturing techniques, plenty of lead-free roof flashing alternatives are now readily available.

Lead-free flashing provides the same watertight seal but is often much easier to install than lead-flashing alternatives. Considering the environmental threat and health risks when it comes to lead vs lead-free roof flashing, the move to lead-free roof flashing makes sense.

Roof Flashing On Australian Homes

Flashing materials can vary considerably and suit various cost considerations, architectural designs, and compatibility with adjoining materials. In addition to providing a waterproof barrier, the flashing should integrate with a building's design elements. It should also be flexible enough to work into the crevices and contours of a structure where flashings are needed.

In Australia, flashing is typically available in two types: exposed or concealed.

Exposed roof flashing:

Exposed flashing is usually constructed of sheet metal, and concealed flashing of metal, or flexible material is used around wall penetrations like door openings and windows.

Concealed roof flashing:

Concealed flashing typically uses lead-free replacements such as QACO-FLEX, rubber or rubberised asphalt.

Which Is The Best Roof Flashing Product In Australia?

There are many factors to consider when choosing what flashing solution you wish to install on your home to keep it watertight and looking its best. For generations, lead flashing has been used simply because there weren't materials or technology available to create anything better. Unfortunately, there were no lead-free roof flashing solutions.

Luckily with the advent of Polymer Engineering, impressive new materials such as Polyisobutylene or Butyl rubber were developed to be used in a wide range of applications. One of these applications in the Australian market, known as the lead-free' roof flashing of choice' by builders and roofers, is QACO-FLEX.

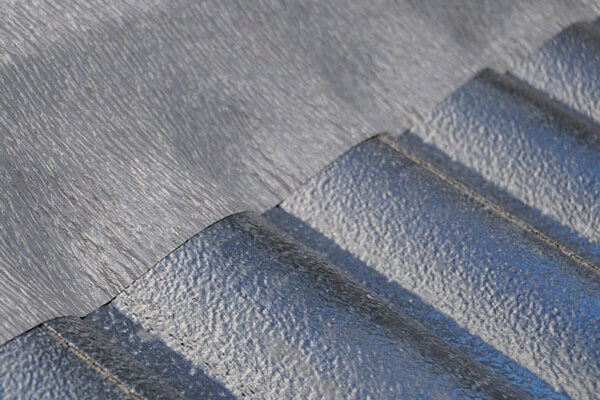

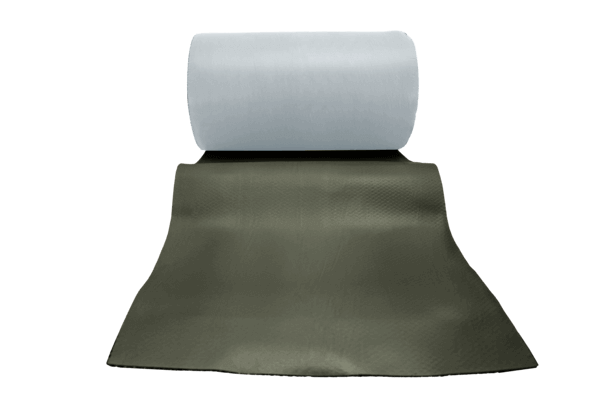

QACO-FLEX lead-free roof flashing is part of a new generation of materials designed to replace lead in roofing products. In terms of functionality, it's more than 50% lighter than lead, with the lightweight composite made of stretchable aluminium moulded into a special type of polymer rubber. It is environment-friendly, maintains the roof's integrity, and provides superior waterproofing qualities.

Key benefits of QACO-FLEX lead-free roof flashing include:

- Made from Polyisobutylene rubber and aluminium making it safe for installers and the environment

- Lightweight and easy to handle for quick installation

- Suitable for all roof shapes and types

- Requires no special tools needed and is 50% quicker to install compared to lead flashing

- It can be stretched and cut with a knife, shears or scissors

- The internal aluminium mesh provides rigidity and a lasting memory when dressed to the roof surface

- Chemically bonds to itself to create a watertight seal

- Can stretch up to 50% in length and 15% in width

- Delivered in grey, black and red; can be painted over to suit roof colour

- It comes in rolls ranging from 250mm x 5m to 1m x 5m or custom lengths

Looking For The Best Valued Lead-Free Roof Flashing?

Testimonials

What Customers Love About QACO-FLEX

“I was looking for a lead-free roof flashing and I couldn't be happier with QACO-FLEX. It's not only a great product but is the best valued lead-free roof flashing on the market!”

Chris Mathers

Roofer“QACO-FLEX arrived in a very timely manner and is exactly how I visualised it to be and is very effective at replacing the older style lead flashing.”

Mark Florimo

Builder“QACO-FLEX is very easy to cut and easy to position. It also sticks into position extremely well and looks excellent. I highly recommend the QACO-FLEX!”